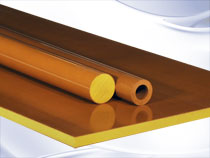

Duratron® T4301 PAI

اطلاعات عمومی

Product Overview

- Maintains strength and stiffness to 500°F (260°C)

- Minimal expansion rate to 500°F (260°C)

- Excellent wear resistance in bearing grades

- Able to endure harsh thermal, chemical and stress conditions

With its versatile performance capabilities and proven use in a broad range of applications, Duratron polyamide-imide (PAI) shapes are offered in extruded, injection molded, and compression molded grades.

Duratron PAI is the highest performing, melt processable plastic. It has superior resistance to elevated temperatures. It is capable of performing under severe stress conditions at continuous temperatures to 500°F (260°C). Parts machined from Duratron stock shapes provide greater compressive strength and higher impact resistance than most advanced engineering plastics (See Figure 22).

Duratron PAI’s extremely low coefficient of linear thermal expansion and high creep resistance deliver excellent dimensional stability over its entire service range (see Figure 23). Duratron PAI is an amorphous material with a Tg (glass transition temperature) of 537°F (280°C). Duratron PAI stock shapes are post-cured using procedures developed jointly by BP Amoco and Quadrant. This eliminates the need for additional curing by the end user in most situations. A post-curing cycle is sometimes recommended for components fabricated from extruded shapes where optimization of chemical resistance and/or wear performance is required.

For large shapes or custom geometries like tubular bar, compression molded Duratron PAI shapes offer designers the greatest economy and flexibility. Another benefit of selecting a compression molded grade is that resins are cured, or “imidized” prior to molding which eliminates the need to post-cure shapes or parts fabricated from compression molded shapes.

Popular extrusion and injection molding grades of Duratron PAI are offered as compression molded shapes. Typically, you can identify a compression molded grade as having a second digit of “5” in the product name.

General Purpose Wear and Friction Parts

This Duratron PAI is primarily used for wear and friction parts. It offers a very low expansion rate, low coefficient of friction and exhibits little or no slip-stick in use. Duratron T4301’s flexural modulus of 1,000,000 psi, is higher than most other advanced engineering plastics. This grade excels in severe service wear applications such as non-lubricated bearings, seals, bearing cages and reciprocating compressor parts.

مشخصات فنی

- دمای ذوب(Melting temperature)℃ 450

- جذب آب در 24 ساعت(Water absorption after 24h)% 0.3

- چگالی(density)g/cm3 1.45

- تنش کششی(Tensile strength)MPa 110

- ضریب الونگیشن(Elongation)% 5

- استحکام ضربه ای(Charpy impact strength)kj/m2 4

- سختی(Shore)86

- سختی(Rockwell)70

- میزان مقاومت الکتریکی(Volume resistivity)ohm.m 1E+12

- دی الکتریک(Dielectric)5.4